Hybrid construction

For me, a hybrid construction is a mix of methods and/or materials, that enables a boat to be built economically without sacrificing shape to any great extent. The most suitable method or material is used for its most compatible location. While strip cedar can achieve most rounded shapes, it’s not ideal for flat panels, as its strength is mainly along the strip. Cheaper, less labor intensive methods might do the job, so read on.

Although this section will show some interesting examples of how wood construction has evolved to permit almost any sectional form to be created with some ingenuity, there is really no limit to how hybrid options may develop. New materials and new ways to use them are appearing all the time and individuals with inventive minds will doubtless find interesting ways of using them. While anything that saves weight will be welcomed, one must never lose sight of the forces in any particular part of the boat and be sure to use materials that are locally strong enough. Tows of carbon fiber might become a more common reinforcing as lighter but perhaps weaker materials become available .. but again, a balance must be achieved by matching materials with elasticity that is not too far apart, or the less-elastic material will take all the load.

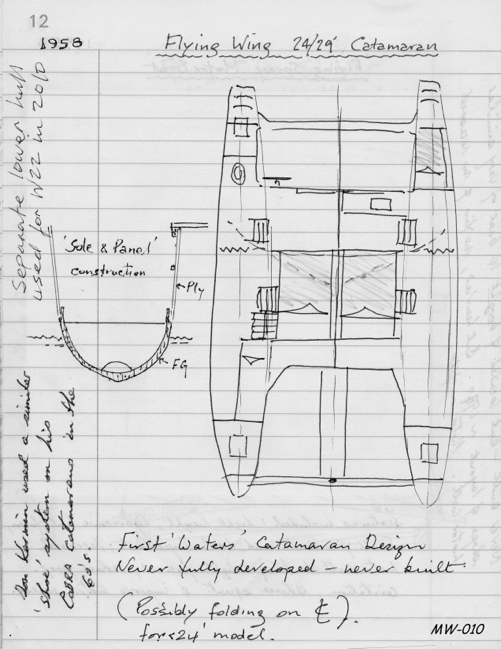

Back in 1958, I sketched out my first catamaran - using a hybrid construction. Here is an early page from my Record Book to show what it looked like. Fiberglass had not long started to show up and as a recent graduate, I was excited about its possibilities. But it was heavy and seemed overly flexible for flat panels. So I sketched out this idea to mould the lower hull in glass but link it to the flatter topsides of light plywood – lapping its edge into a rebate moulded into the top of the glass solepiece. But as my budget was not able to build the boat, it never became a reality. So you can imagine my surprise and delight after arriving in North America, when in the early 60’s, I read about a new catamaran by a Don Karmin on the eastern seaboard, that used virtually the same idea! What’s more, Don also ‘made it happen’, building a number of his Cobra Cats in the 34’-40’ size range … all using the same concept. If I remember correctly, Don called his solepiece ‘a shoe’.

I became (and still am) a great fan of the Cobra Cats, as his combination of a rounded sole with narrow flat sides, also supports my thinking on how to build a multihull of low wave resistance, as his sides are almost vertical and the hulls very slim. Sure, this is clearly not a roomy cat, but for performance and comfort at sea, they proved hard to beat, winning most of their races in the NY area.

More recently, Mike Leneman of California has used the same concept for his L7. Sadly, this boat is no longer being built, but for a while, Mike was offering fiberglass sole-pieces for the 3 hulls of his 7m trimaran … with plywood topsides that lapped on to the fiberglass in the same manner as I had sketched out in 1958 ... clearly unknown to him at the time. In this case, Mike framed up the upper hull to fairly rigidly fit the moulded sole-piece as shown here for an ama.

With this concept in my head for some 50 years, it’s not surprising that perhaps the latest design to use this system, is my own W22, where the lower part is actually built of either cedar or rigid foam strips, with glass either side. In this case, no recess is required, as the topside plywood simply laps against a flange molded on the top of the

stripped part, so forming a knuckle just above the waterline. Once glassed over and faired off, this looks totally professional, and it’s no longer apparent to the viewer how easily the form was achieved. These pics show both the lower solepiece of foam strips, and then, with the flatter topside panels being added. Hybrid wood construction might include a lower hull of cedar strips with plywood topsides.

Once faired and painted, the joint is no longer visible. See W22 here and hull at left.

So hybrid construction has lots of potential and it’s up to designers and builders to keep exploring the possibilities, within limits of strength, weight, durability and cost.

"New articles, comments and references will be added periodically as new questions are answered and other info comes in relative to this subject, so you're invited to revisit and participate." —webmaster

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"