Information on the home-buildable Waters-Wing carbon-fiber mast

A very detailed (90+ page) illustrated manual is now available for building a very efficient and good looking CF wing mast of Lengths from 8 to 11m, that in 2021-> sells for US$199 (plus $11 Paypal fee), with rights to build ONE mast. (This design is now referred to as the Waters Wingmast Mk.l, to differentiate from a more elliptical Mk.ll design that, while using the same basic construction principle, has since been developed for wingmasts in the 11-16m range). This Manual became available early in 2025, after the prototype Mk ll had been well tested .. from 2022-2024. The extensive Mk.ll manual has its cost based partly on size, so for its introduction, will be US$150 + L^2, (L=mast in M) ie: $294 + 6% PP fee for a 12m mast.

NOTE: If you are registered as having previously purchased the Mk.l Manual but now wish to upgrade to the Mk.ll without first building the Mk.l, you can be credited US$100 on the cost of the Mk.ll Manual. But if you wish to build both designs, this rebate does not apply. But for perspective, these Manuals cost little more than 1% the current cost of a pro-built CF wingmast.

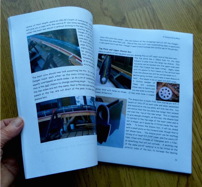

The Mark l manual contains over 100 photos and sketches and shows all details, as well as defining all the procedures and cloths required for each mast size. A photo record from another builder is also included for more guidance. See also reviews shared below.

This enables one to build a CF wing mast at 10-12% of the cost of a pro-built mast, so the savings are very significant. The trade-off is that, without vacuum-bagging** and/or resin infusion, the weight is a little greater, but still measurably less than an alum mast of the same section, as well as being stiffer and less expensive. The 8m mast, c/w all fittings and the diamond stays, weighs around 45 lbs - but keep in mind that this design covers a wing section of close to 3:1 (depth to width) and not the more typical mast section of about 1.5:1 that of course uses much less material but is far less efficient aerodynamically. The advantage of the deeper rotating wing (approaching 3:1) is in its performance efficiency, and this more than offsets the slightly extra weight. While most of the performance gain is upwind, wingmasts can also work as a vertical end plate on deep reaches.

**NOTE: For those who have the equipment and experience to get the resin and bags on quickly, there are now suggested ways to add vacuum-bagging to this build method. Details available for anyone who purchases the manual

By May 2020, six masts to this Mk.l design had been built, with the prototype now extensively tested over multiple seasons. Many others are now under construction. See below for Comments.

The completed mast has proven strong and durable and has a structural advantage over most other masts by having a built-in transverse web for its full height, rather like the 'spar' within a plane's wing. This not only adds considerably to buckling resistance but also creates 2 compartments; one for the internal halyards, and a larger one that may remain sealed as an air chamber, depending on how halyards are arranged. Also note that this mast has an attractive built-in taper above the hounds, in both width and depth. If built and finished well, this mast can look totally professional.

The purchase process is defined below:

----------------------------------------------------------------------------------------------------------

Added April 2024: Introducing the Mk.ll Waters Wingmast ... and how to purchase.

By 2020, numerous inquiries were coming in for similar wingmasts but of greater length. One particular inquiry was from a boat builder with significant experience with resin-infusion, so it was decided to look into this quite seriously. This builder had a racing trimaran in Germany and wanted to upgrade his performance as much as possible, and needed a new CF wingmast of 12.2m. So I made all new design sketches and calculated the CF shell structure required and got this builder up-and-running.

Andre Baetz did a great job of this Mk.ll prototype so the result 'looked' great, but a new mast like this needed to be very well tested if it was to be the prototype for a whole new series. Normally, such testing is done progressively, as it was for the Mk.l, but in this case, it was quite a 'baptism-by-fire'.

Andre Baetz did a great job of this Mk.ll prototype so the result 'looked' great, but a new mast like this needed to be very well tested if it was to be the prototype for a whole new series. Normally, such testing is done progressively, as it was for the Mk.l, but in this case, it was quite a 'baptism-by-fire'.

Mk.ll Test Results

In June 2022, about 10 days after its completion, the first Mark ll Waters Wingmast was really put to the test. It was stepped on a racing Farrier F82S and though untried and untested, entered into one of the most gruelling races in Europe ... a 900 mile race up the entire length of the Baltic, starting in Wismar, close to Denmark and ending in Torn, only 100 miles from the Arctic Circle. To sail this distance and back home again, involves over 2000 nmls of sailing over about 2 weeks, with winds from all directions.

Well, the mast performed flawlessly and helped this relatively small boat beat other multis that were up to 50% longer, and break a 7 year old race course record by 17 hours for the fastest time ever by a multihull for this race. If you want more of the story, .. HERE it is.

A year later, the same boat and wingmast competed in the same race in 2023 but now in lighter conditions, yet once again she finished 1st Multihull proving Andre's 2022 performance was no fluke. The mast came through with flying colors with only a couple of minor issues that have been resolved for the latest Manual..

As explained in this Intro ... the Mk.ll Manual took a while to complete as it's very detailed. By my reckoning, it NEEDS to be very detailed, as by far the majority of such masts are a 'first-time experience' for the builder, so the small details that can make all the difference, cannot be left 'to past experience', as there frequently is none. As Andre kept a good photo record of his work, buyers of the Mk.ll Manual will also receive a copy of these photos too, & that should fill in any gaps in the Manual text.

So how to proceed to Purchase the Waters Mark.ll Wingmast Manual

The first thing is to sign the Waiver that is at the bottom of this page, and return it to: trimarandesign@earthlink.net

Then, the fee for the appropriate WingMast Manual (see first paragraph on this page) is sent by PayPal to the same email address. and you will then be sent the PDF files within 48 hours. .. typically much faster. Data for the 11m mast is now included in both Manuals, so that is the overlapping cross over point. For the Mk.l Manual, one can interpolate the dimensions, thicknesses and cloth lay-up to suit the final mast length but for the Mark.ll, there is a one specific Lamination Data Sheet sent out for each mast size. If your trimaran has a beam much in excess of 55% of the mast height, please contact the mast designer as you may need to use a larger section to handle this unusually high righting moment, depending on your ama buoyancy, sail area etc.

When not to install a wingmast. Please note that these wingmasts are for a multihull that does not 'sail on its ear', so such wingmasts are not recommended for mono's, unless stabilized with foils to sail fairly upright. After all, you want the extra lift to 'pull you along', not add to your heeling moment !

** For those wondering: why the Mkll, and what are the differences with the Mk l ?

Basically, the Mk.ll uses the same construction method, but as the nose of the Mk l is a radius closely based on the mast width, this starts to get too blunt and large for the larger mast sections over say 90mm wide. So for the Mkll, the nose is made more elliptical. Also, the rotation force of the larger masts can get quite high, so the pivot (and central web) has been moved back relative to the chord dimension. In addition, the supporting cables are attached to a swivelling (not fixed) beak, the base pivot support is stronger, and the masthead cap can be arranged to take up to 4 internal halyards.

As most larger masts over 12m will use a track for batten-slides or cars, that's been factored in. So the main Mk.ll design assumes a mast track, but information on how to replace this with a bolt rope (for masts 12m & under), is also given in the Mk.ll Manual. Note that while the elliptical nose gives a finer, less resistant air entry, the more rounded nose of the Mk1 will be less critical to stalling when the approach angle to the apparent wind is less well matched.

Also, because of the larger size and material cost, a few jigs are suggested to further control construction tolerances for the larger Mkll, added steps that are just not considered necessary for the Mk.l masts under 11m. The Manual for the Mk.ll wingmast also explains how and where, vacuum bagging and/or resin infusion can be used to advantage.

For those wanting more information on the differences between the Mk.l Wingmast & the Mk.ll ... GO HERE

Should a builder be interested to build more than one mast, a full manual must be purchased for the first mast, with a special fee applicable to cover the Design Royalty, depending on the mast size. Contact the designer for this. (The design and testing of these masts ran well into 5 figures, so just a small part of this cost is shared by each builder via the Manual purchase).

Because inquiries are also coming in for masts in excess of 14m, a slightly modified Mk.lll mast is offered for masts over 14.5m, that will use the same basic design as for the Mk.ll, but have double diamonds and possibly other tweaks, to safely deal with the greater loads. This is now mostly covered in the Mk/ll Manual

Mike Waters, n.a. for Small Trimaran Design

.

Waters WOOD Wingmast:

The build method is described through 3 sheets of detailed plans and a 15+6 page Manual full of illustrations. Material cost (using high quality) was about US$200 (in 2019) and the plans sell for US$120 via PayPal. This design has now been used for numerous wingmasts of this format and works fine for its intended use. The CF design is however inevitably more efficient as the material enables it to be stiffer and slightly slimmer. Again, please accept, sign and return a copy of the Mast Waiver below before ordering or I will not be able to send out the plans.

Comment by the designer (2020)

One point that I will add that I’ve not seen mentioned elsewhere, is this.

Because a rotating wing mast assures a better entry to the flow around the soft sail that sets behind it, the smaller the sail hoisted, the more proportionally efficient the rig becomes. I became very aware of this when setting a small but high aspect storm mainsail behind my own wingmast a few years back, and was very impressed how efficiently this small rig performed. Most boats, certainly all cruising dinghies, struggle in high wind and waves to get anywhere upwind. For them, the W17 is a total revelation. Despite the increased waves due to higher winds, I have been able to make 9 kts (!) to windward and even hit 14.4kt with my W17 on one wild reach … and this storm mainsail is only about 4m2 ! Check here and watch the Storm Mainsail performance Video

As a performance-loving octogenarian, I can tell you it’s a really fun way to sail. Fast but Safer, so I enthusiastically recommend a small but high-aspect mainsail with a wing mast to all builders, for all high wind use. This may be 'over 18kts' for someone athletic who likes to hang out, but this sail can make things a lot more comfortable, easier and safer over 15 kts for the older sailor.

Comments by builders:

"My CF-wingmast is finally done, and bringing it out of the basement yesterday was like a birth to me! It is truly a spectacular piece of complex design and fabrication inventiveness. I am both proud of the final product and impressed with the build method, all the way through. The build-manual was key to my success. It is extremely complete in design and structural detail and also very helpful with build techniques. In summary, building the carbon fiber wing mast was a three month project which I will never forget. I have a mast that rivals or equals professionally built ones and is probably even stronger. I also learned a raft of new skills, saved quite a chunk of money, but beyond all of that I have the tremendous reward and pride that comes from this special DIY project. It is actually quite amazing to work through this unique design with a process that enables one to start with a bunch of soft carbon fiber cloth and a couple of gallons of epoxy, and end up successfully constructing a state of the art rotating carbon fiber wing mast. Thank you Mike!" Jim van N, USA, 2020 See photo of JIM'S MAST .... first time builder too ! ---- >>

"I am having so much fun making this mast! Just to see each piece come together from a piece of cloth and resin to form a rigid, strong yet lightweight structure, is quite amazing. The design is clever and intriguing and your detailed manual takes most of the stress out of this build so giving me, the builder, every confidence that I will end up with a good result. Thanks a million!" Joe-V: USA, 2019

"I have read through the CF mast manual and am very impressed with your techniques and also how comprehensive the manual is. The depth at which you cover the subject makes this a real bargain for anyone who has thought about building their own wing mast in carbon. It's really a gem of a publication".

Alan-J, WA-USA, 2019.

"Hi Mike; thanks for the CF-mast building instructions. It's a great piece of work and I thank you very much that you share your techniques and knowledge in this way".

Günter-K, Germany, 2017

"I really enjoyed building my carbon fiber wing mast and would even enjoy doing it all over again! I am very happy with my results and the skills I developed during the building and now have the confidence to use carbon fiber far more than I used to. Even the cosmetics of my mast came out acceptably well as I've received many compliments from friends ... "You BUILT that !!". My mainsail also fits the sail groove perfectly so I am really looking forward to getting it out on the water".

Ron-E, USA, 2015

"I received the manual and it looks great! It is indeed an ingenious construction method and the incorporation of a central web further adds to my confidence in the end result. The amount of detail is stunning and everything makes a lot of sense (I skimmed it twice and then gave it a more thorough read-through). I find it well-written and the detail gives a potential builder a lot of confidence that this can indeed be done. There is nothing about this method [from my perspective], that is any more difficult than typical boat building, and most of it even seems a lot simpler than that. So, great work, and I see many more masts being built using this method. I also completely understand your need for a waiver and would do the same in your position, as after all, you have no control over the end product materials, construction or use."

Todd-B: USA, 2015 (builder/sailor, experienced with composite construction)

======================================================================================

WAIVER: (CLICK HERE for the PDF)

By requesting these wing-mast plans, I confirm having read and agreed to these Terms and Conditions:

Licence: As purchaser of these Mast Plans and/or Manual, and on behalf of a potential builder / operator, I acknowledge that I am granted a licence for the building of ONE mast only. I agree to request an expanded licence if planning to build more than one. As noted under general Terms & Conditions, information in this Manual is considered IP (Intellectual Property), so no refund can be granted after this Manual has been delivered.

Copyright: I further acknowledge that these plans, drawings, and building manual are copyright material and that any distribution of their content or part of, requires prior written permission from the designer (or his assigns). Any disregard of this will be deemed a violation of copyright.

Acknowledgement of Indemnity: I acknowledge that while the designer may be fully qualified to design this mast with adequate strength for its intended pleasure use, he has no control over the final selection of materials, quality of workmanship, or weather conditions to which the mast may be subjected. As potential builder / owner, I therefore agree to accept the following:

Waiver: That, neither the builder, owner or any skipper, nor their heirs or assigns, will take legal action against the designer, his heirs or associates, for any damage of property, loss of use, injury or even death arising out of construction and use of this design, whether considered as caused by any deemed negligence of the designer or otherwise, and agree to indemnify and hold harmless, the designer, his heirs, successors, and associates, from any loss, liability, damage or cost that may arise relating to the building and use of this design.

| Signed: | Date: | ||

| Name: | |||

| Email Address: | |||

Link to Contact Page