Installing Stringers and Gunwales—dealing with twist etc.

First make sure all frames and the stem are square to the centerline and also vertical. If you diagonally brace one bulkhead perpendicular to the Build Platform, a batten tack-nailed over the keel line to the others, will hold them vertical too.

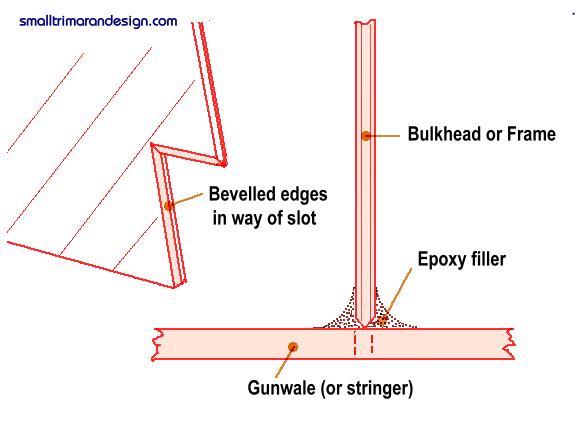

As far as frame/bhd slots are concerned, it's nice to have a snug fit, as all stays in place while the stringers etc. are fitted. However, with the now common use of thickened epoxy, I prefer to bevel away the sides of the frame/bhd so that most of the final bond will be in that epoxy and not just in a snug slot, with insufficient space to hold any glue.

As far as frame/bhd slots are concerned, it's nice to have a snug fit, as all stays in place while the stringers etc. are fitted. However, with the now common use of thickened epoxy, I prefer to bevel away the sides of the frame/bhd so that most of the final bond will be in that epoxy and not just in a snug slot, with insufficient space to hold any glue.

Because side stringers are typically at half height and bonded in on 3 sides, it's usually best to start with them as they are the most effective for stabilizing the frames and bulkheads. Prefitting is of course always required, especially to determine the bevel cuts at the bow and also at the stern if applicable. The W17 stringers are arranged to conveniently lap over the stempiece, and in this case, they are cut with a 1:8 slope. (The W17 gunwale cut-back is closer to 1:6.)

(Don't forget to keep the pieces you cut off, as they will be very useful for keeping clamps in place when you bond the ends to the stem—see photo.)

(Don't forget to keep the pieces you cut off, as they will be very useful for keeping clamps in place when you bond the ends to the stem—see photo.)

To hold the stringers in place, all one needs are 2 or 3 webbing straps to pull them into the bulkhead or frame slots. Add clamps at the bow and perhaps a screw at the stern and you're all set.

Because of the greater bend plus perhaps some sheer to cope with, gunwales can sometimes be asked to twist a little too. This can readily be handled by using long clamps screwed to the gunwale and then using a strong cord between the ends to apply the twist. If you use a double chord, you can easily tension this chord with what we used to call a 'Spanish windlass'—a piece of wood between the 2 cords that is then rotated to twist and tighten them (see photo).

But do not take this too far. These longitudinal wood members need to be permitted to take their own fair line and if the twist is more than you can readily do by hand, then it will likely stress the joint to the frame too much and risk to crack later. But the clamp approach is still useful for giving that 'hand twist' while the epoxy cures.

But do not take this too far. These longitudinal wood members need to be permitted to take their own fair line and if the twist is more than you can readily do by hand, then it will likely stress the joint to the frame too much and risk to crack later. But the clamp approach is still useful for giving that 'hand twist' while the epoxy cures.

With the stringers already locked and bonded in place, the gunwales can be strapped up to them, going across to the opposite stringer to give a little upward force to well seat the gunwale in its open slot.

The webbing straps are also very useful to hold the stringers etc at the ready yet still give access to apply the epoxy.

Read more Construction Tips & Techniques.

"New articles, comments and references will be added periodically as new questions are answered and other info comes in relative to this subject, so you're invited to revisit and participate." —webmaster

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"